Threadformer

Unscrewing Molds Made Easy!

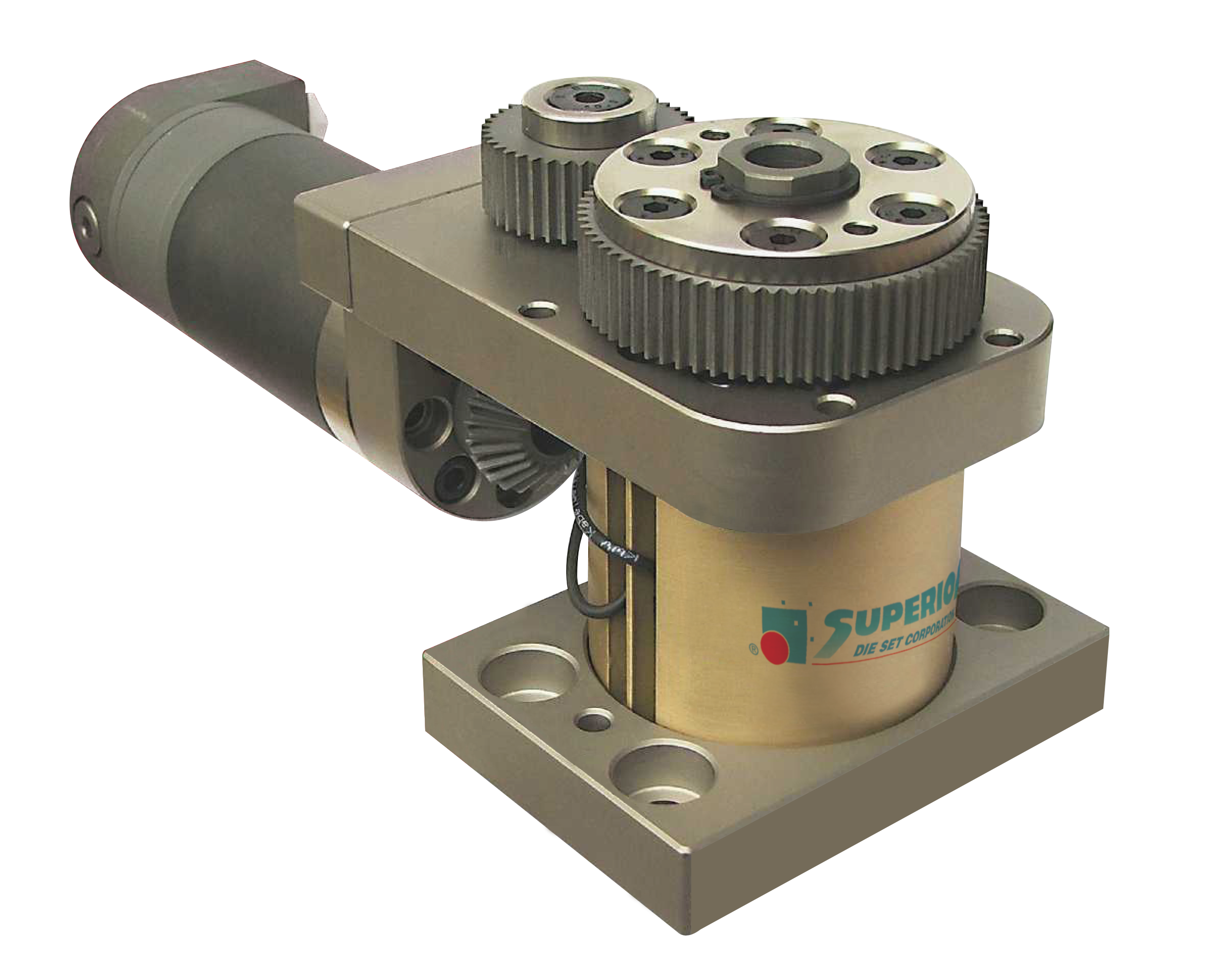

Made in the USA, Threadformer™ unscrewing devices provide a very simple solution to complex unscrewing molds. Precise, sturdy and cost-efficient, they reduce production and labor costs by consistently delivering reliable, trouble-free service, on time.

The Threadformer is ideal for low-cavitation jobs. It takes on the difficult task of unscrewing molds without compromising the part and delivers maximum accuracy without any hassle. With a compact, yet highly powerful hydraulic motor, the Threadformer provides the high torque needed while providing a positive core stop to deliver optimal precision.

Easy to install and operate, the Threadformer also comes in a right-angle unit for water cooling or upstanding cores. Learn more

Sample Video

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Suspendisse varius enim in eros elementum tristique. Duis cursus, mi quis viverra ornare, eros dolor interdum nulla, ut commodo

Features

- Telescope guide system provides compact design

- Powerful hydraulic motor for rapid unscrewing action – 3 different, interchangeable motor options available depending on torque vs. speed demands (8, 32 and 50 bar)

- Demolds both right and left-hand thread

- Supports long thread depths, pitches, and types – unscrews to 70mm

- Compact single, twin, right angle, mini and multi-unit drive unit designs

- Require minimal maintenance for high-production use

- Offer retrofit option for new or existing injection molds

- Can be mounted at any angle or within the mold – with only 2 bolts

- Repeatable, precise core stopping ability within .001” or better – each unit uses high-precision magnetic field sensors, and thread depth is determined by a fixed stop on the mold – signal adapter transmits sensor signal with delay, preventing occurrence of switching inaccuracies

- Also available in special versions, e.g., with extended core holder and matching heat insulation plate

- The unscrewing devices are rated for operating temperatures up to 70°C (158 F)

Die Set Product Line

Related Resources

Check out our Threadformer brochure for more information.

Start Your Project With Superior Die Set Corporation

Thank you for your interest! Please fill out the following form and we will contact you as soon as possible.

"*" indicates required fields